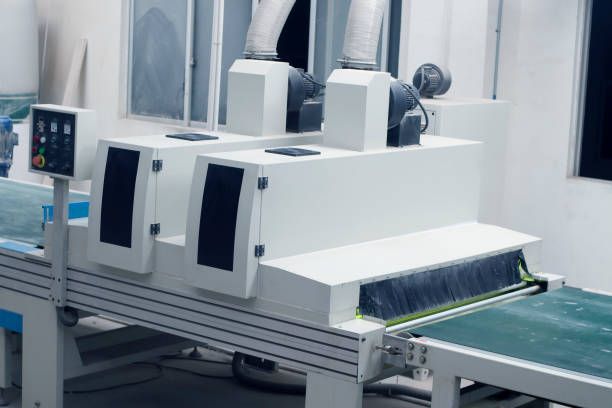

What Are the Main Types of UV Curing Machines?

UV treatment machines are devices that use ultraviolet light to cure or treat materials such as ink, coatings, glue and resins. This technique was introduced as a sharp and cleaner alternative to traditional heat or air drying methods.

Over the years, UV treatment has expanded from printing and packaging to electronics, medical equipment and the production of motor vehicles. These machines vary in design and application, with types from large conveyor belt -based systems to portable handheld devices. Understanding their main types helps industries to choose the most appropriate option for efficiency and quality.

Importance

UV treatment machines mean something because they solve many challenges in industries:

Speed: They significantly reduce treatment time compared to traditional methods.

Energy efficiency: Many systems use lower power than heat -based drying, stability targets.

Consistency: UV improves the quality of the light product, treating steadily.

Versatility: Machines can handle a wide range of materials, from flexible plastic to hard metals.

Environmental benefits: Some systems match environmentally friendly practice, reduce emissions and solvent use.

Industries such as printing, packaging, electronics, automotive industry and health services benefit from these benefits, making UV treatment machines an important part of modern production.

Newer updates

Last year, UV treatment technology has developed with many remarkable trends:

LED UV growth (2024–2025): LED-based UV treatment systems gain popularity due to long-term life, low heat production and energy savings.

Minorization: Compact UV treatment devices are developed on small scales and portable applications.

Smart control system: Integration of sensors and software provides the possibility of monitoring real -time treatment of treatment procedures.

Stability effort: Many manufacturers launch mercury -free machines that match global environmental goals.

Extensive application: UV treatment is expanded in 3D printing and medical equipment, reflecting its adaptability.

These updates highlight how technology keeps up with industrial needs and environmental priorities.

Laws or guidelines

UV treatment machines are affected by safety, environmental and production rules. Guidelines vary from the country, but include common focus areas:

Mercury regulations: Many countries, under the Minaata Convention on Mercury, phase out the mercury-based UV lamps in favor of LED options.

Safety rules in the workplace: Agencies such as OSHA in the United States set guidelines for UV -light risk for safety for workers.

Environmental standards: Regulations can limit the release of volatile organic compounds (VOC), which can treat UV an attractive match tool.

Energy efficiency program: Some governments encourage the use of low -energy therapy techniques through encouragement or certificates.

Industry standards: International standards for organizations such as ISO ensure that machines meet quality and show benchmarks.

Compliance with these guidelines ensures safe use and helps companies meet stability and legal requirements.

Main Types of UV processing machines

UV processing machines come in separate forms, compatible with each specific applications. The main types include:

| Type | Description | Common Uses |

|---|---|---|

| Conveyor Systems | Large machines with conveyor belts that pass items under UV lamps. | Printing, packaging, coatings on large items |

| Spot Curing Systems | Deliver focused UV light to a small, specific area. | Electronics, medical devices, adhesives |

| Flood Curing Systems | Cover larger surfaces with broad UV exposure. | Screen printing, large panels, coatings |

| Handheld Devices | Portable tools for flexible use in smaller or hard-to-reach areas. | On-site repairs, small assembly work |

| LED UV Systems | Use LED lamps instead of mercury vapor lamps; energy-efficient and eco-friendly. | 3D printing, electronics, packaging |

This limit allows industries to choose based on size, accurate and environmental goals.

Tools and resources

Many equipment and resource companies and professional UV treatment machines can help learn or informed decisions:

UV intensity meter: Equipment to measure the strength and stability of UV light.

Cost calculator: Online calculator to compare energy cost between LED UV and Mercury Lamp System.

Industry Association: Organizations such as Redtech International offer training, research and networking opportunities.

Security guide: OSHA or EU-SASHA resources on UV security in the workplace.

Software equipment: Process monitoring system that traces time, temperature and UV exposure.

They simplify resource decisions, increase safety and improve general efficiency.

Question to ask

Does UV processing machines use the most?

Printing, packaging, electronics, cars and medical equipment are among the main industries that use UV treatment machines.

Is the LED UV system better than traditional people?

LED UV systems are more energy efficient, produce low heat and are mercury-free. However, traditional systems are sometimes preferred for specific materials that provide better response to their light spectrum.

Is UV safe for workers?

Yes, when the security guidelines are followed. Workers should use protective equipment as UV-blocking glass and follow risk standards in the workplace.

How long does the UV MEAC lamp last?

Mercury lamps usually live up to 1000-2,000 hours, while LED lamps can last 20,000 hours or more, which can reduce the cost of requirements.

Can UV processing machines be used in 3D printing?

Yes, UV treatment is widely used to harden resins in 3D printing and get accurate, durable results.

Final thoughts

UV treatment machines have become necessary in modern production and production. Quickly makes their ability to provide consistent and environmentally friendly results them valuable in industries.

With newer innovations in LED UV technology, these machines have been determined to play even more role in the coming years, with the improvement of stability efforts and expanding applications. Supported by security and environmental regulations, UV treatment technology continues to develop by meeting the needs of different fields.

For companies and professionals ensure a number of UV treatment machines better alternatives and long -lasting efficiency.